Video

Applicationem

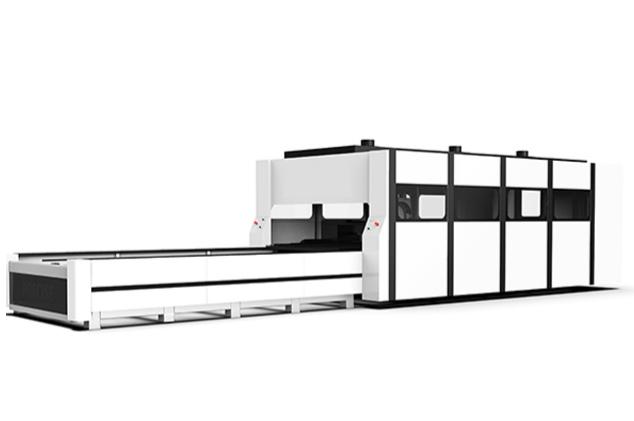

Lorem Materias Fibra Laser secans Machina

Fiber laser machina secans ferro immaculatam, chalybem carbonem, mitem chalybem, mixturam chalybem, chalybem galvanizatum, chalybem pii, ferrum ver, linteum titanium, linteum galvanizatum, linteum ferreum, linteum inox, aluminium, cuprum, aes et alia metalla, metallum. bractea, fistula et fistula, etc.

Applicabilis Industria Fibra laser scindens Machina

Fibra laseris machina secans multas industrias adhiberi potest.Exempli gratia: machinae partes, electricae, sheet metalla fabricatio, scrinium electrica, coquinaria, tabula elevator, instrumenta ferraria, clausura metallica, litterae signum vendo, lucernas accensis, artificia metallica, ornamentum, ornamentum, instrumenta medica, partes automotivae et alia metalla incisura agrorum. .

Sample

Configurationis

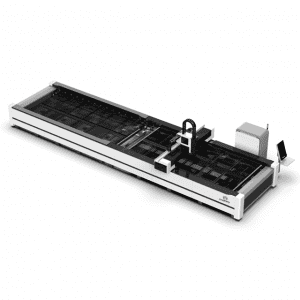

Duplex Fast Exchange tabularum

Metallum corpus in hoc dromone curatio DC°C caloris subiit, et intra fornacem XXIV horis refrigeratur.Postquam haec perfecta est, discursum est utens machinae plano-millingae et iuncta dioxide carbonis utens.Hoc efficit ut altas vires et 20 annos vitae servitutis habeat.

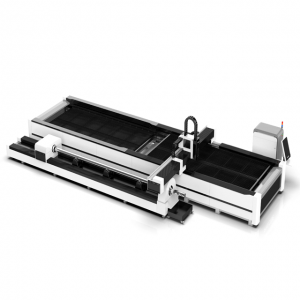

Altius Safety Level

Totum circa tegumentum tutelae laser radiatio et pollutio segregat, offerens altiorem gradum securitatis.Fumus et pulvis in sectione productus automatice colligentur ad aream mundam operativam, quae apta est ad vexillum Europae CE.Dolor magna ratio adiuvat reducere ratem accidentis.

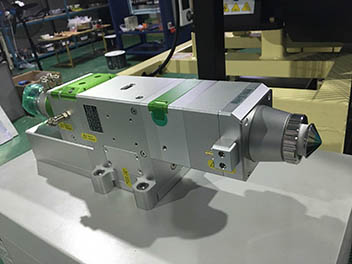

Helvetia Raytools Laser Head

Hoc caput laseris ad varias focorum longitudines applicatur, quae machinae instrumenti sistendi ratio reguntur.Punctum arx sponte aptabitur in processu secando ad optimum effectum secandum diversarum crassitudinum schedae metallicae.Perforatio umbilicus augens longitudinis, perforationis focalis longitudinis seorsim ponendo et arx longitudinem secans, accurationem secans emendare.

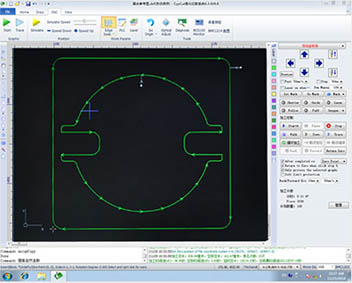

CYPCUT Systema Imperium

CYPCUT Systema temperantiae fibri nostri laseris machinae secantis intellegere potest intelligentem extensionem graphics incisionis et importare plurium graphicorum, optimizing sectionis ordines ipso facto, margines exquisite et positionis automaticae investigandi.Systema moderandi optimam programmandi et programmandi programmandi modalem adhibet, experientiam operationis attonitus praebet, efficaciter augens utendo schedae metallo et extenuando vastitatem.Simplex et velox ratio operationis, efficientis et accuratae instructionum secantium, efficaciter experientiam utentis emendavit.

BCS100 Capacitive Height Controller

BCS100 altitudinis capacitivae moderatoris (infra post BCS100 appellatum) fibra nostra laser machina secans est summus fabrica machinalis moderandi quae methodo moderandi usus-loop.BCS100 etiam singularem communicationem Aer (TCP/IP protocollum) praebet, facile consequi potest multa munera cum programmate CypCut, qualia sunt automataria vestigia altitudinis, articulatae penetrans, progressivae perforans, ora quaerunt, leapfrog, arbitrarium occasum altitudinis elatum. Secandi caput. Eius responsionis rate etiam valde emendatus est.Praesertim inservo imperium aspectus, eius celeritas ac diligentia cursus meliores esse debet manifesto quam alia similia producta, propter algorithmum occlusum duplicem velocitatis et positionis.Terror sup- ferit dum tabulam et ultra ripam.Ora deprehensio et latae inspectioni suscipe.

Parametri technici

| Apparatus Model | KP Series |

| Necem | 1070nm |

| Secans Area | 3000* 1500mm/4000*2000mm/6000*2000mm/6000*250mm |

| Laser Power | 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W / 12KW / 15KW / 20KW / 30KW |

| X / Y-axis Positioning Sagaciter | 0.03mm |

| X/Y-axis Repositioning Accuracy | 0.02mm |

| Maximilianus.Acceleratio | 1.5G |

| Maximilianus.seriei celeritas | 140m/min |

Ipsumque parametri

| Morbi consequat | 1000W | 1500W | 2000W | 3000W | 4000W | |

| Materia | Crassitudo | celeritas m / min | celeritas m / min | celeritas m / min | celeritas m / min | celeritas m / min |

| Carbon chalybe (Mitis Steel) | 1 | 8.0--10 | 15--26 | 24--32 | 30--40 | 33--43 |

| 2 | 4.0--6.5 | 4.5-6.5 | 4.7--6.5 | 4.8--7.5 | 15--25 | |

| 3 | 2.4--3.0 | 2.6--4.0 | 3.0--4.8 | 3.3--5.0 | 7.0--12 | |

| 4 | 2.0--2.4 | 2.5--3.0 | 2.8--3.5 | 3.0--4.2 | 3.0--4.0 | |

| 5 | 1.5--2.0 | 2.0--2.5 | 2.2--3.0 | 2.6--3.5 | 2.7--3.6 | |

| 6 | 1.4--1.6 | 1.6--2.2 | 1.8--2.6 | 2.3--3.2 | 2.5--3.4 | |

| 8 | 0.8--1.2 | 1.0--1.4 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | |

| 10 | 0.6--1.0 | 0.8--1.1 | 1.1--1.3 | 1.2--2.0 | 1.5--2.4 | |

| 12 | 0.5--0 | 0.7--1.0 | 0.9--1.2 | 1.0--1.6 | 1.2--1.8 | |

| 14 | 0.5--0 | 0.8--1.0 | 0.9--1.4 | 0.9--1.2 | ||

| 16 | 0.6-0.8 | 0.7--1.0 | 0.8--1.0 | |||

| 18 | 0.5--0 | 0.6--0 | 0.6--0.9 | |||

| 20 | 0.5--0 | 0.5--0 | ||||

| 22 | 0.3--0 | 0.4--0.8 | ||||

| > > > > > | 1 | 18--25 | 20--27 | 24--50 | 30--35 | 32--45 |

| 2 | 5--7.5 | 8.0--12 | 9.0--15 | 13--21 | 16--28 | |

| 3 | 1.8--2.5 | 3.0--5.0 | 4.8--7.5 | 6.0--10 | 7.0--15 | |

| 4 | 1.2--1.3 | 1.5--2.4 | 3.2--4.5 | 4.0--6.0 | 5.0--8.0 | |

| 5 | 0.6--0 | 0.7--1.3 | 2.0-2.8 | 3.0--5.0 | 3.5--5.0 | |

| 6 | 0.7--1.0 | 1.2-2.0 | 2.0--4.0 | 2.5--4.5 | ||

| 8 | 0.7-1.0 | 1.5--2.0 | 1.2--2.0 | |||

| 10 | 0.6--0 | 0.8--1.2 | ||||

| 12 | 0.4--0.6 | 0.5--0 | ||||

| 14 | 0.4--0.6 | |||||

| aluminium | 1 | 6.0--10 | 10--20 | 20--30 | 25--38 | 35--45 |

| 2 | 2.8--3.6 | 5.0--7.0 | 10--15 | 10--18 | 13--24 | |

| 3 | 0.7--1.5 | 2.0--4.0 | 5.0--7.0 | 6.5--8.0 | 7.0--13 | |

| 4 | 1.0--1.5 | 3.5--5.0 | 3.5--5.0 | 4.0--5.5 | ||

| 5 | 0.7--1.0 | 1.8--2.5 | 2.5--3.5 | 3.0--4.5 | ||

| 6 | 1.0--1.5 | 1.5--2.5 | 2.0--3.5 | |||

| 8 | 0.6--0 | 0.7--1.0 | 0.9--1.6 | |||

| 10 | 0.4--0 | 0.6--1.2 | ||||

| 12 | 0.3-0.45 | 0.4--0.6 | ||||

| 16 | 0.3--0 | |||||

| Brass | 1 | 6.0--10 | 8.0--13 | 12--18 | 20--35 | 25--35 |

| 2 | 2.8--3.6 | 3.0--4.5 | 6.0--8.5 | 6.0--10 | 8.0--12 | |

| 3 | 0.5--1.0 | 1.5--2.5 | 2.5--4.0 | 4.0--6.0 | 5.0--8.0 | |

| 4 | 1.0--1.6 | 1.5--2.0 | 3.0-5.0 | 3.2--5.5 | ||

| 5 | 0.5--0 | 0.9--1.2 | 1.5--2.0 | 2.0--3.0 | ||

| 6 | 0.4--0.9 | 1.0--1.8 | 1.4--2.0 | |||

| 8 | 0.5--0 | 0.7--1.2 | ||||

| 10 | 0.2--0 | |||||